Table of Contents

Introduction to Digital Engineering

In today’s ever-evolving technological landscape, the realm of engineering has undergone a profound transformation, transitioning from traditional methods to a dynamic and innovative approach known as Digital Engineering. This groundbreaking discipline integrates cutting-edge digital technologies with traditional engineering principles to revolutionize the design, development, and manufacturing processes across various industries. Let’s embark on a journey to unravel the essence of Digital Engineering and understand its significance in shaping the future of engineering.

Understanding Digital Engineering:

Digital Engineering encompasses a diverse array of methodologies and tools aimed at leveraging digital technologies to streamline and enhance engineering workflows. It encompasses various disciplines, including computer-aided design (CAD), simulation, data analytics, virtual prototyping, and additive manufacturing. By harnessing the power of advanced computational techniques, engineers can create, simulate, and analyze complex systems with unprecedented speed, accuracy, and efficiency.

Key Components of Digital Engineering:

- Computer-Aided Design (CAD): CAD software enables engineers to create detailed 3D models of components and systems, facilitating visualization and simulation throughout the design process. These digital prototypes allow for rapid iteration and optimization, reducing time-to-market and minimizing costly errors.

- Simulation and Modeling: Digital Engineering employs advanced simulation tools to predict the behavior and performance of products under various conditions. From structural analysis to fluid dynamics and electromagnetics, simulations enable engineers to validate designs, optimize performance, and mitigate risks before physical prototyping.

- Data-Driven Decision Making: With the proliferation of sensors and IoT devices, Digital Engineering leverages vast amounts of real-time data to inform design decisions and improve product performance. By integrating data analytics and machine learning algorithms, engineers can gain valuable insights into product usage, maintenance needs, and performance optimization.

- Virtual Prototyping: Virtual prototyping allows engineers to create and test prototypes in a virtual environment, significantly reducing the need for physical prototypes. This not only saves time and resources but also enables early validation of designs, leading to more robust and reliable products.

- Additive Manufacturing (3D Printing): Additive manufacturing technologies have revolutionized the manufacturing process by enabling the creation of complex geometries with unprecedented precision and efficiency. Digital Engineering harnesses the capabilities of 3D printing to rapidly prototype, customize, and manufacture components with minimal waste and lead time.

Significance of Digital Engineering:

The adoption of Digital Engineering methodologies offers several compelling benefits for organizations across industries:

- Increased Efficiency: By automating repetitive tasks and streamlining workflows, Digital Engineering accelerates the design and development process, allowing organizations to bring innovative products to market faster.

- Cost Reduction: Digital Engineering helps minimize material wastage, reduce the need for physical prototypes, and optimize manufacturing processes, leading to significant cost savings over the product lifecycle.

- Enhanced Collaboration: Digital Engineering fosters collaboration among multidisciplinary teams by providing a centralized platform for sharing data, collaborating on designs, and accessing real-time insights, irrespective of geographical locations.

- Improved Product Quality: Through rigorous simulation and testing, Digital Engineering enables engineers to identify and address design flaws early in the development cycle, resulting in higher-quality products and improved customer satisfaction.

- Agility and Innovation: Digital Engineering empowers organizations to adapt quickly to changing market demands, iterate on designs rapidly, and embrace emerging technologies, fostering a culture of innovation and continuous improvement.

Evolution of Digital Engineering

In the digital age, where technology permeates every facet of our lives, the realm of engineering has undergone a profound transformation. From the rudimentary tools of the past to the sophisticated algorithms of the present, the evolution of digital engineering is a testament to human ingenuity and innovation.

The inception of digital engineering can be traced back to the emergence of computers in the mid-20th century. With the advent of these computational machines, engineers gained the ability to simulate complex processes and analyze data with unprecedented speed and accuracy. This marked the beginning of a new era, where traditional engineering practices would be revolutionized by digital technologies.

One of the key milestones in the evolution of digital engineering was the development of Computer-Aided Design (CAD) software. Introduced in the 1960s, CAD revolutionized the way engineers conceptualized and designed products. It allowed for the creation of detailed 2D and 3D models, streamlining the design process and enabling greater precision and efficiency.

As computing power continued to grow exponentially, engineers began to explore the possibilities of Computer-Aided Engineering (CAE). CAE software enabled engineers to simulate the behavior of physical systems under various conditions, allowing for virtual testing and optimization. This not only reduced the need for costly and time-consuming physical prototypes but also facilitated innovation by enabling engineers to explore a wider range of design possibilities.

The integration of digital technologies into the manufacturing process gave rise to the concept of Digital Manufacturing. This approach leverages advanced simulation and optimization techniques to optimize production processes, improve quality, and reduce costs. From additive manufacturing (3D printing) to robotic automation, digital engineering has transformed the way products are manufactured, making production more agile and responsive to changing market demands.

In recent years, the advent of Artificial Intelligence (AI) and Machine Learning (ML) has further propelled the evolution of digital engineering. AI-powered algorithms are being used to automate design tasks, optimize product performance, and predict maintenance requirements. By analyzing vast amounts of data and identifying patterns, AI enables engineers to make data-driven decisions and unlock new insights that were previously inaccessible.

The evolution of digital engineering is not confined to any single industry or discipline. From aerospace and automotive to healthcare and construction, digital technologies are reshaping the way we design, build, and operate systems and infrastructure. The rise of interdisciplinary approaches such as Systems Engineering and Digital Twinning further underscores the interconnected nature of modern engineering practices.

Looking ahead, the evolution of digital engineering shows no signs of slowing down. As technologies such as Virtual Reality (VR), Augmented Reality (AR), and Internet of Things (IoT) continue to mature, engineers will have even more powerful tools at their disposal. These technologies promise to further enhance collaboration, visualization, and decision-making, ushering in a new era of innovation and efficiency.

Key Components of Digital Engineering

In the rapidly evolving landscape of technology, digital engineering stands as the cornerstone of innovation and progress. From groundbreaking software solutions to cutting-edge hardware advancements, digital engineering encompasses a broad spectrum of disciplines aimed at revolutionizing how we interact with the digital world. But what exactly are the key components that make up this dynamic field? Let’s delve into the intricate framework of digital engineering and uncover its essential building blocks.

- Software Development: At the heart of digital engineering lies software development, where intricate algorithms and code are crafted to breathe life into digital systems. Whether it’s developing mobile applications, web platforms, or complex enterprise solutions, software development forms the backbone of digital engineering.

- Hardware Integration: While software powers the digital realm, hardware integration ensures seamless interaction between the virtual and physical worlds. From embedded systems to IoT devices, integrating hardware components into digital systems requires meticulous planning and execution, often involving sensors, actuators, and microcontrollers.

- Data Analytics: In an era defined by data, the ability to extract actionable insights is paramount. Data analytics plays a pivotal role in digital engineering, enabling organizations to harness the power of big data to drive informed decision-making, optimize processes, and uncover hidden patterns and trends.

- Cybersecurity: With the proliferation of digital technologies, safeguarding sensitive information and protecting against cyber threats is of utmost importance. Cybersecurity forms an integral part of digital engineering, encompassing measures such as encryption, authentication, and intrusion detection to mitigate risks and ensure the integrity of digital systems.

- User Experience (UX) Design: In the age of user-centric design, creating intuitive and engaging user experiences is essential for the success of digital products and services. UX design focuses on understanding user needs and behaviors, translating them into seamless interfaces and interactions that enhance usability and satisfaction.

- Cloud Computing: As the demand for scalability, flexibility, and accessibility grows, cloud computing has emerged as a game-changer in digital engineering. Leveraging cloud infrastructure allows organizations to deploy and manage applications with unprecedented agility, enabling rapid innovation and cost optimization.

- Artificial Intelligence (AI) and Machine Learning (ML): AI and ML represent the frontier of digital engineering, empowering systems to learn from data, adapt to changing environments, and perform tasks that traditionally required human intelligence. From predictive analytics to autonomous systems, AI and ML are driving transformative advancements across industries.

- DevOps Practices: In the pursuit of continuous integration and delivery, DevOps practices have become synonymous with agile development and operational efficiency. By fostering collaboration between development and operations teams, DevOps accelerates the pace of innovation while ensuring the reliability and stability of digital systems.

- Quality Assurance (QA) and Testing: In a landscape where software bugs can have far-reaching consequences, rigorous QA and testing are imperative. From automated testing frameworks to manual QA processes, ensuring the quality and reliability of digital solutions is essential for building user trust and maintaining brand reputation.

- Digital Transformation Strategies: Beyond individual components, digital engineering encompasses holistic strategies for driving organizational change and innovation. From adopting agile methodologies to embracing digital-first mindsets, digital transformation strategies lay the foundation for leveraging technology to achieve business objectives and stay ahead in a competitive landscape.

Advantages of Digital Engineering in Product Development

In today’s fast-paced technological landscape, the role of digital engineering in product development has become increasingly paramount. From concept creation to final production, digital engineering revolutionizes the traditional product development process, offering a myriad of advantages that propel innovation and efficiency. Let’s delve into the remarkable benefits that digital engineering brings to the table.

- Enhanced Collaboration and Communication: Digital engineering facilitates seamless collaboration among multidisciplinary teams regardless of geographical locations. Through digital platforms and tools, engineers, designers, and stakeholders can effortlessly share ideas, designs, and feedback in real-time. This level of connectivity fosters synergy, accelerates decision-making processes, and ensures everyone is on the same page throughout the product development lifecycle.

- Streamlined Design Iterations: Gone are the days of laborious manual iterations. Digital engineering empowers designers to rapidly iterate and refine product designs using advanced modeling and simulation techniques. By leveraging virtual prototyping and computer-aided design (CAD) software, engineers can explore countless design variations, identify potential flaws early on, and optimize product performance while reducing time-to-market.

- Cost and Time Efficiency: Digital engineering minimizes the need for physical prototypes and extensive testing phases, significantly reducing both time and costs associated with traditional product development. By simulating real-world scenarios and conducting virtual tests, engineers can validate designs, predict product behavior, and mitigate risks before investing in physical prototypes. This iterative approach not only accelerates the development cycle but also lowers production costs and enhances product quality.

- Optimized Performance and Sustainability: Through digital simulations and analyses, engineers can fine-tune product specifications to maximize performance while minimizing environmental impact. Digital engineering enables the optimization of material usage, energy efficiency, and manufacturing processes, fostering the development of sustainable products that meet evolving regulatory standards and consumer demands.

- Agile and Adaptive Development: In today’s dynamic market landscape, agility is key to staying competitive. Digital engineering empowers companies to embrace agile development methodologies, enabling rapid iterations and continuous improvements based on real-time feedback and market insights. By leveraging digital twins and predictive analytics, businesses can monitor product performance in real-world conditions, identify opportunities for enhancement, and swiftly respond to changing customer needs and market trends.

- Innovative Problem-Solving: Digital engineering unlocks new realms of creativity and innovation by breaking traditional design constraints and fostering out-of-the-box thinking. By combining data-driven insights, computational algorithms, and advanced visualization techniques, engineers can tackle complex design challenges, explore novel solutions, and push the boundaries of what’s possible in product development.

- Seamless Integration with Industry 4.0 Technologies: As we transition towards the era of Industry 4.0, digital engineering serves as a cornerstone for integrating emerging technologies such as artificial intelligence (AI), Internet of Things (IoT), and additive manufacturing (3D printing) into the product development ecosystem. By harnessing the power of digital twins, connected devices, and data analytics, companies can create smart, interconnected products that deliver unparalleled value and customer experiences.

Enhanced Collaboration through Digital Engineering

In today’s fast-paced and interconnected world, collaboration lies at the heart of innovation and progress. Businesses across various industries are constantly seeking ways to enhance collaboration among their teams to drive efficiency, creativity, and ultimately, success. One such avenue that has emerged as a game-changer in fostering collaboration is digital engineering.

Digital engineering encompasses a range of technologies and methodologies aimed at leveraging digital tools and platforms to streamline the product development process. From concept ideation to design, prototyping, testing, and production, digital engineering integrates various disciplines and stakeholders into a cohesive ecosystem. However, its impact extends beyond mere technical processes; it fundamentally transforms the way teams collaborate and communicate.

One of the key elements driving enhanced collaboration through digital engineering is the breaking down of silos. Traditionally, different departments within an organization often operate in isolation, leading to communication barriers and inefficiencies. Digital engineering facilitates cross-functional collaboration by providing a centralized platform where stakeholders from diverse backgrounds can collaborate in real-time. Whether it’s engineers, designers, marketers, or project managers, everyone can contribute their expertise and insights, leading to holistic solutions that address multiple aspects of a problem.

Moreover, digital engineering promotes transparency and visibility throughout the product lifecycle. Through shared dashboards, project management tools, and collaborative platforms, team members can access real-time updates, track progress, and identify potential bottlenecks or issues. This level of transparency fosters accountability and ensures that everyone is aligned towards common goals, thereby minimizing misunderstandings and enhancing overall productivity.

Furthermore, digital engineering enables virtual collaboration, breaking the barriers of geographical distance and time zones. With the rise of remote work and global teams, the ability to collaborate seamlessly irrespective of physical location has become increasingly critical. Through virtual design environments, cloud-based collaboration tools, and immersive technologies such as virtual reality (VR) and augmented reality (AR), teams can collaborate as if they were in the same room, enhancing communication, problem-solving, and decision-making processes.

Additionally, digital engineering facilitates iterative design and rapid prototyping, empowering teams to quickly iterate on ideas, gather feedback, and refine solutions in a collaborative manner. By leveraging simulation tools, 3D modeling software, and digital twins, teams can simulate real-world scenarios, test hypotheses, and validate designs before committing to costly physical prototypes. This iterative approach not only accelerates the product development cycle but also fosters a culture of innovation and continuous improvement.

Improving Accuracy and Efficiency in Prototyping

In the realm of product development, prototyping serves as a crucial stage bridging concepts and tangible outcomes. It’s the experimental playground where ideas come to life, and innovations take shape. However, the process isn’t without its challenges. From maintaining accuracy to optimizing efficiency, there are various hurdles that teams face. But fear not, for there are strategies and tools available to streamline and enhance the prototyping process.

Understanding the Importance of Prototyping

Before delving into improvement strategies, it’s essential to grasp why prototyping holds such significance. Prototypes serve as tangible manifestations of abstract ideas. They allow teams to test functionalities, gather feedback, and iterate swiftly. By identifying flaws early on, prototypes save both time and resources in the long run. Moreover, they facilitate effective communication among team members and stakeholders, aligning everyone towards a shared vision.

Strategies for Enhancing Accuracy

Accurate prototyping is the cornerstone of successful product development. Here are some strategies to ensure precision in your prototypes:

- Clear Objectives and Requirements: Start by defining clear objectives and requirements for your prototype. Understanding the end goal helps in crafting prototypes that are focused and aligned with the desired outcomes.

- User-Centric Design: Incorporate user feedback early in the prototyping process. By prioritizing user needs and preferences, you ensure that the final product resonates with its intended audience.

- Iterative Testing: Embrace an iterative approach to prototyping. Test early and test often to identify and address potential issues before they escalate. Each iteration brings you closer to a refined and accurate prototype.

- Use of Advanced Tools: Leverage advanced prototyping tools and technologies to enhance accuracy. From CAD software for precise 3D modeling to simulation tools for testing complex functionalities, investing in the right tools can significantly improve the accuracy of your prototypes.

Strategies for Improving Efficiency

Efficiency is another crucial aspect of prototyping, especially in today’s fast-paced development environment. Here are some strategies to boost efficiency without compromising on quality:

- Streamlined Processes: Streamline your prototyping processes to eliminate unnecessary steps and reduce lead times. Identify bottlenecks and inefficiencies and implement measures to streamline workflows.

- Collaborative Platforms: Embrace collaborative platforms that facilitate real-time collaboration among team members. Cloud-based prototyping tools allow team members to work together seamlessly, regardless of their location.

- Reusable Components: Develop a library of reusable components and templates that can be easily repurposed across different projects. This not only saves time but also ensures consistency across prototypes.

- Automation: Explore automation opportunities wherever possible to speed up repetitive tasks. From automated testing scripts to code generation tools, automation can significantly reduce manual effort and accelerate the prototyping process.

Cost Reduction through Digital Engineering Techniques

In today’s fiercely competitive business landscape, cost reduction stands as a paramount objective for enterprises across industries. Amidst this pursuit, digital engineering emerges as a transformative force, offering innovative techniques to streamline processes and drive efficiencies. Leveraging advanced technologies such as AI, machine learning, and automation, digital engineering holds the key to unlocking significant cost-saving opportunities while enhancing overall operational effectiveness.

Embracing Digital Transformation: At the heart of cost reduction through digital engineering lies the concept of digital transformation. This entails the integration of digital technologies into all aspects of business operations, fundamentally altering how organizations operate and deliver value to customers. By harnessing digital tools and methodologies, enterprises can optimize their processes, eliminate inefficiencies, and ultimately drive down costs.

Enhancing Operational Efficiency: One of the primary avenues through which digital engineering facilitates cost reduction is by enhancing operational efficiency. Through the implementation of intelligent automation solutions, repetitive tasks can be automated, freeing up valuable human resources to focus on more strategic initiatives. Whether it’s streamlining supply chain processes, optimizing manufacturing workflows, or automating administrative tasks, digital engineering empowers organizations to achieve more with less.

Predictive Maintenance and Asset Optimization: Another area where digital engineering techniques prove invaluable is in predictive maintenance and asset optimization. By leveraging data analytics and IoT sensors, organizations can gain real-time insights into the performance of their assets and equipment. This enables proactive maintenance interventions, preventing costly breakdowns and downtime. Additionally, predictive analytics can optimize asset utilization, ensuring that resources are deployed efficiently to maximize returns while minimizing operational expenses.

Agile Development and Iterative Improvement: In the realm of software development, digital engineering methodologies such as Agile offer a powerful framework for cost reduction. By adopting Agile practices, organizations can accelerate time-to-market, reduce development costs, and enhance product quality through iterative improvement cycles. Through constant collaboration, feedback, and adaptation, Agile teams can deliver value more efficiently, ensuring that resources are allocated judiciously to meet evolving business needs.

Leveraging Cloud Computing: Cloud computing represents another cornerstone of cost reduction through digital engineering. By migrating infrastructure and applications to the cloud, organizations can eliminate the need for costly hardware investments and maintenance. Cloud services offer scalability, flexibility, and cost-efficiency, allowing businesses to pay only for the resources they consume. Furthermore, cloud-based solutions enable remote collaboration and access to advanced computing capabilities, empowering organizations to innovate without the burden of hefty capital expenditures.

Enhanced Product Lifecycle Management (PLM) with Digital Engineering

In today’s fast-paced and highly competitive business landscape, companies across industries are constantly seeking innovative ways to streamline their operations and stay ahead of the curve. One area that has witnessed significant transformation is Product Lifecycle Management (PLM), where digital engineering has emerged as a game-changer. By leveraging advanced digital technologies throughout the product lifecycle, businesses can enhance efficiency, reduce time-to-market, and drive unparalleled innovation. Let’s delve deeper into how digital engineering is revolutionizing PLM processes.

Digital engineering encompasses a comprehensive set of technologies and methodologies that enable the creation, simulation, and optimization of products and processes in a virtual environment. From conceptualization to manufacturing and beyond, digital engineering tools provide companies with unprecedented insights and capabilities to design, analyze, and iterate their products with precision and agility.

One of the key benefits of integrating digital engineering into PLM is the ability to accelerate product development cycles. Traditional PLM processes often involve lengthy design iterations, physical prototyping, and testing phases, which can significantly delay time-to-market. However, with digital engineering tools such as computer-aided design (CAD), simulation software, and virtual prototyping platforms, companies can expedite the design and validation process, allowing for faster iterations and quicker decision-making.

Moreover, digital engineering facilitates collaboration and communication across cross-functional teams involved in the product development lifecycle. Through cloud-based PLM platforms and collaborative tools, stakeholders from design, engineering, manufacturing, and supply chain can seamlessly collaborate in real-time, breaking down silos and ensuring alignment throughout the product journey. This enhanced collaboration not only improves efficiency but also fosters innovation by leveraging diverse perspectives and expertise.

Another critical aspect of digital engineering in PLM is its ability to optimize product performance and reliability. By leveraging advanced simulation and modeling techniques, engineers can accurately predict how a product will behave under different conditions, identify potential issues early in the design phase, and optimize performance parameters accordingly. This predictive capability not only improves product quality but also reduces the risk of costly recalls and warranty claims down the line.

Furthermore, digital engineering enables companies to embrace a more sustainable approach to product development and lifecycle management. By simulating the environmental impact of products throughout their lifecycle, businesses can identify opportunities to reduce resource consumption, minimize waste, and enhance overall sustainability. From material selection to end-of-life disposal, digital tools empower companies to make data-driven decisions that align with their sustainability goals and regulatory requirements.

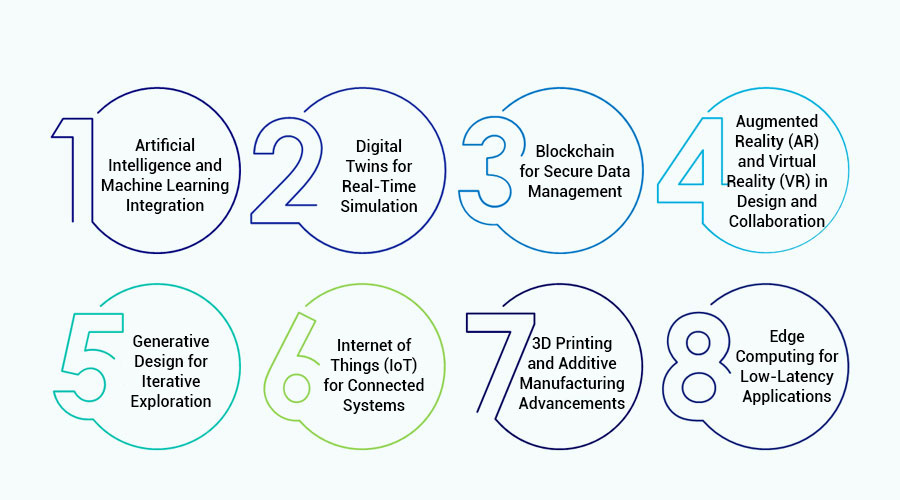

Future Trends and Innovations in Digital Engineering

In the dynamic landscape of technology, digital engineering stands as a beacon of innovation, constantly evolving to meet the demands of an ever-changing world. As we peer into the future, several trends and innovations are poised to shape the trajectory of digital engineering, revolutionizing industries and redefining the way we approach design, development, and implementation.

- Artificial Intelligence and Machine Learning Integration: One of the most significant trends in digital engineering is the integration of artificial intelligence (AI) and machine learning (ML) algorithms. These technologies are revolutionizing traditional engineering processes by enabling predictive analytics, autonomous systems, and intelligent decision-making. From optimizing designs to automating routine tasks, AI and ML are set to become indispensable tools in the engineer’s arsenal.

- Digital Twins for Real-Time Simulation: Digital twins, virtual replicas of physical assets, are becoming increasingly sophisticated, allowing engineers to simulate real-world scenarios with unparalleled accuracy. In the future, digital twins will play a pivotal role in predictive maintenance, performance optimization, and risk management across various industries, including manufacturing, healthcare, and urban planning.

- Blockchain for Secure Data Management: The rise of blockchain technology holds immense promise for digital engineering, particularly in ensuring secure and transparent data management. By leveraging blockchain, engineers can create tamper-proof records of design iterations, supply chain transactions, and asset ownership, enhancing trust, integrity, and accountability throughout the product lifecycle.

- Augmented Reality (AR) and Virtual Reality (VR) in Design and Collaboration: AR and VR technologies are blurring the lines between the physical and digital worlds, revolutionizing the way engineers visualize, interact with, and collaborate on complex projects. From immersive design reviews to virtual prototyping, AR and VR are empowering engineers to iterate rapidly, identify potential issues early, and streamline communication across multidisciplinary teams.

- Generative Design for Iterative Exploration: Generative design algorithms are enabling engineers to explore a vast array of design possibilities based on specified constraints and objectives. By harnessing the power of computational algorithms, engineers can efficiently generate and evaluate numerous design alternatives, leading to innovative solutions that optimize performance, minimize material usage, and reduce environmental impact.

- Internet of Things (IoT) for Connected Systems: The proliferation of IoT devices is ushering in a new era of connected systems, where sensors, actuators, and smart devices seamlessly interact to monitor, control, and optimize processes in real-time. In digital engineering, IoT technology enables remote monitoring, predictive maintenance, and data-driven decision-making, paving the way for smarter, more efficient infrastructure and services.

- 3D Printing and Additive Manufacturing Advancements: Additive manufacturing technologies, such as 3D printing, continue to advance rapidly, offering new possibilities for rapid prototyping, customization, and on-demand production. From aerospace components to biomedical implants, 3D printing is revolutionizing traditional manufacturing processes, unlocking new levels of design freedom, cost-efficiency, and sustainability.

- Edge Computing for Low-Latency Applications: As the demand for real-time processing and analytics grows, edge computing is emerging as a critical enabler for latency-sensitive applications in digital engineering. By moving computational tasks closer to the source of data generation, edge computing reduces latency, bandwidth usage, and dependency on centralized infrastructure, making it ideal for time-critical applications like autonomous vehicles, industrial automation, and smart grids.

Top Digital Engineering and Its Benefits Companies

In today’s rapidly evolving technological landscape, digital engineering stands as a beacon of innovation for companies seeking to streamline operations, enhance productivity, and stay ahead of the competition. This cutting-edge approach to engineering combines traditional methodologies with digital tools and technologies, revolutionizing the way businesses design, develop, and deliver products and services. Let’s delve into the top benefits that digital engineering offers to companies across various industries.

-

-

Next Big Technology:

Focus Area

- Mobile App Development

- App Designing (UI/UX)

- Software Development

- Web Development

- AR & VR Development

- Big Data & BI

- Cloud Computing Services

- DevOps

- E-commerce Development

Industries Focus

- Art, Entertainment & Music

- Business Services

- Consumer Products

- Designing

- Education

- Financial & Payments

- Gaming

- Government

- Healthcare & Medical

- Hospitality

- Information Technology

- Legal & Compliance

- Manufacturing

- Media

-

- Enhanced Collaboration: Digital engineering fosters seamless collaboration among multidisciplinary teams, regardless of geographical locations. Through cloud-based platforms and collaborative software solutions, engineers, designers, and stakeholders can collaborate in real-time, share insights, and iterate on designs more efficiently. This collaborative approach promotes innovation and ensures that all stakeholders are aligned throughout the product development lifecycle.

- Improved Quality and Innovation: By harnessing the power of digital engineering, companies can deliver products of superior quality while driving innovation. Advanced simulation and modeling tools enable engineers to perform detailed analysis and optimization, identifying potential issues early in the design phase and iterating rapidly to achieve optimal results. This iterative process not only enhances product quality but also fosters a culture of innovation within the organization.

- Agility and Adaptability: In today’s fast-paced business environment, companies must be agile and adaptable to respond to changing market demands quickly. Digital engineering empowers companies to iterate rapidly, experiment with new ideas, and pivot as needed without incurring significant time or cost penalties. This agility allows businesses to stay ahead of the curve, capitalize on emerging opportunities, and maintain a competitive edge in the market.

- Data-Driven Decision Making: Digital engineering generates vast amounts of data throughout the product lifecycle, from design and development to testing and maintenance. By harnessing this data through analytics and machine learning algorithms, companies can gain valuable insights into customer preferences, market trends, and product performance. These insights enable data-driven decision-making, empowering companies to make informed choices that drive business growth and profitability.

- Sustainability and Environmental Impact: In an era of increasing environmental awareness, digital engineering plays a crucial role in promoting sustainability and reducing the environmental impact of products and processes. Through optimization algorithms and lifecycle assessments, companies can minimize resource consumption, reduce carbon emissions, and design products that are more energy-efficient and environmentally friendly.